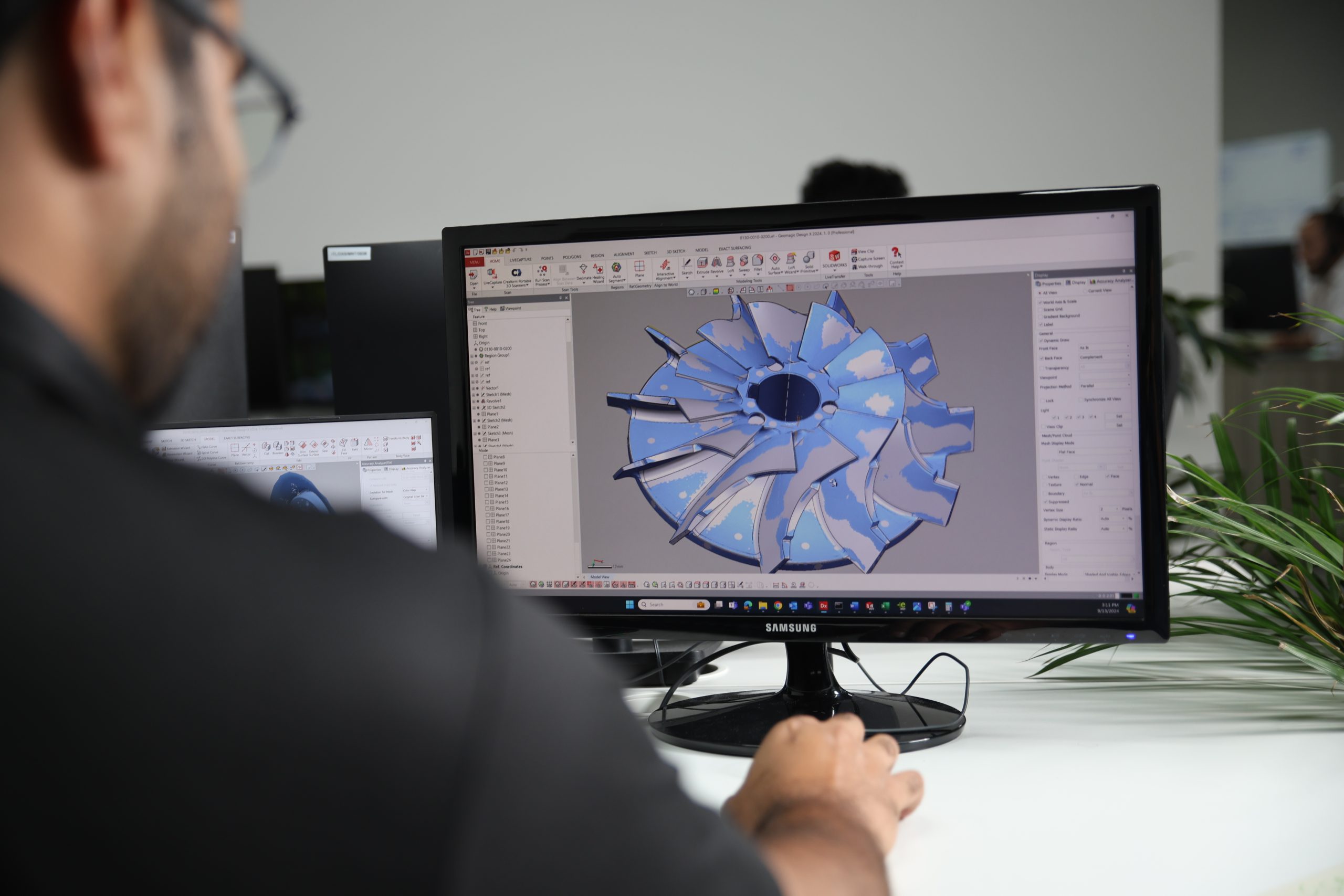

The digitization of spare parts is reshaping how industries manage critical components. The process begins with a physical part, followed by 3D scanning or advanced data capturing, digital modeling, and finally the creation of a digital twin, a precise virtual replica of the original part. Once validated, the digital twins are stored in a digital spare parts library, making them instantly accessible for on-demand production whenever needed.

This shift away from traditional, reactive spare parts strategies reduces downtime, tackles obsolescence, and builds supply chain resilience. Here are three reasons why digital twins are becoming the foundation of modern spare part supply chains:

1. Faster Availability & Reduced Lead Times

Traditional spare parts management relies on maintaining large physical inventories, which are costly, inefficient, and often result in obsolete or unused stock. With digital twins, parts are stored as data, not hardware. Instead of waiting 12-30 weeks (or more) for OEMs and international shipping, operators can access validated digital files from their digital spare parts library and source components on demand.

For industries like oil and gas, utilities, and power generation, where downtime can cost millions, the shift from months to weeks is transformative.

Key benefits:

- Immediate access to a digital spare parts library

- Reduced downtime and operational losses

- Lower risk of parts becoming obsolete

2. Accuracy, Quality & Continuous Improvement

Digital twins capture exact specifications, including geometry, materials, and performance requirements. This ensures repeatability and reliability in every reproduced part. Unlike traditional inventories that may degrade or become outdated, digital twins preserve a part’s “as-designed” state indefinitely.

They also enable continuous improvement. If operating conditions change, designs can be updated and revalidated before production. This flexibility ensures that spare parts remain current, optimized, and aligned with technical standards.

Key benefits:

- Precision and accuracy in every spare part

- Continuous updates to reflect evolving needs

- Preservation of critical part data for legacy equipment

3. Supply Chain Agility & Resilience

Global supply chains are under constant pressure, from geopolitical events to transportation delays. Digital twins help operators minimize exposure by enabling localized production. Once parts are digitized, companies can rely on regional partners or certified facilities to manufacture components closer to the point of use.

This reduces logistics costs, minimizes lead times, and cuts dependence on international suppliers. It also lowers warehouse costs by reducing physical stockpiles, freeing up capital tied to slow-moving or obsolete parts.

Key benefits:

- Reduced dependence on long, uncertain supply chains

- Lower warehousing costs and inventory waste

- Faster turnaround with localized production

Digital twins are not just a technological upgrade; they are the foundation of spare parts digitization strategies. By enabling on-demand availability, ensuring accuracy, and strengthening supply chain resilience, digital twins help operators secure uptime, cut costs, and extend asset lifecycles.

For energy, oil & gas, and industrial operators, the shift from reactive inventories to proactive, digital spare parts libraries is no longer optional; it is mission-critical.

Immensa is leading this transformation as the Global Leader for Digital Spare Parts, helping companies digitize their critical components and build supply chains ready for the future.

Frequently Asked Questions

What is a digital twin in spare parts management?

A digital twin is a validated digital replica of a physical spare part, created through 3D scanning/advanced data capturing, and modeling. It is then stored in a digital library, ready for on-demand production.

How do digital twins support spare parts digitization?

They serve as the output of the digitization process, ensuring spare parts are available digitally, reducing downtime, and eliminating reliance on obsolete or delayed inventories.

Why are digital twins important for supply chains?

Digital twins enable localized, on-demand production, reduce lead times from months to days, and strengthen supply chain resilience against global disruptions.

Which industries benefit most from digital twins?

Energy, oil & gas, power utilities, and industrial operators benefit the most, as downtime in these sectors can cost millions of dollars.

How does Immensa support digital twin adoption?

Immensa helps companies digitize their spare parts, build secure digital libraries, and ensure validated on-demand production through trusted local partners.