Why Spare Parts Digitization is Essential for Energy & Industrial Operators

In asset-heavy industries such as oil & gas, power generation, and utilities, downtime is measured in millions. Yet, despite the high stakes, many companies still rely on outdated spare parts strategies: depending on OEM lead times, overstocking warehouses, or scrambling for suppliers after a failure occurs.

These reactive spare parts strategies are no longer sustainable. Global supply chain disruptions, aging infrastructure, and equipment obsolescence are exposing operators to risks that traditional sourcing cannot solve. The solution is clear: spare parts digitization is no longer optional; it is the foundation for future-proof operations.

The Cost of Obsolescence and Delay

Unplanned downtime costs energy and industrial operators an estimated $149M+ per year. A single failed compressor, turbine, or pump can halt production for weeks. For example, a delayed impeller shipment caused more than two weeks of halted operations at a major energy facility, all because the part was sourced overseas with no alternative available.

And this is not an isolated case:

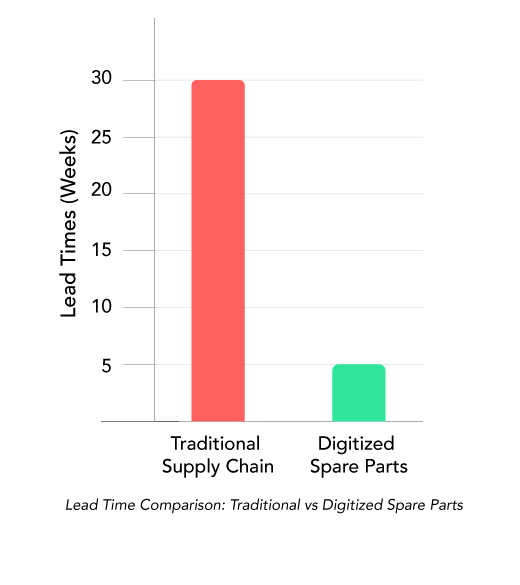

- Standard lead times now range from 12 to 30 weeks.

- Complex or legacy parts can take up to 12 months to arrive.

To mitigate this, companies often overstock. But studies show that up to 40% of storeroom spare parts are slow-moving or obsolete, tying up millions in idle capital.

Key takeaway: Reactive models don’t reduce risk; they prolong and amplify it.

Why Traditional Supply Models Fail Today

The traditional spare parts model, which features centralized OEM manufacturing, long global supply chains, and bloated physical inventories, was built for stability. Today’s world demands agility.

Operators face:

- Aging infrastructure → many OEM parts are discontinued.

- Supply chain volatility → backlogs, shipping delays, and trade disruptions.

- Low flexibility → reactive sourcing leaves no room for resilience.

This creates fragile supply networks that fail when operators need them most.

The Proactive Alternative: Spare Parts Digitization

Leading operators are adopting proactive spare parts strategies centered on digitization.

This approach includes:

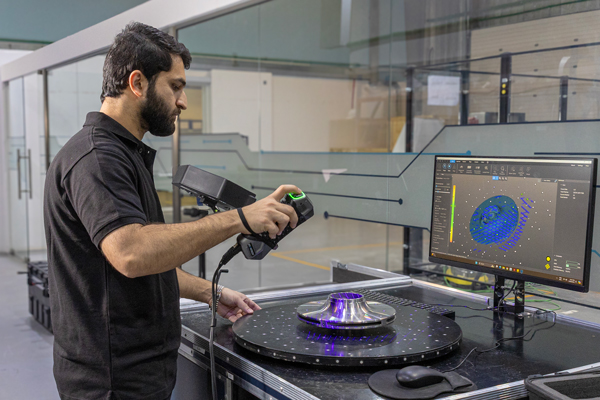

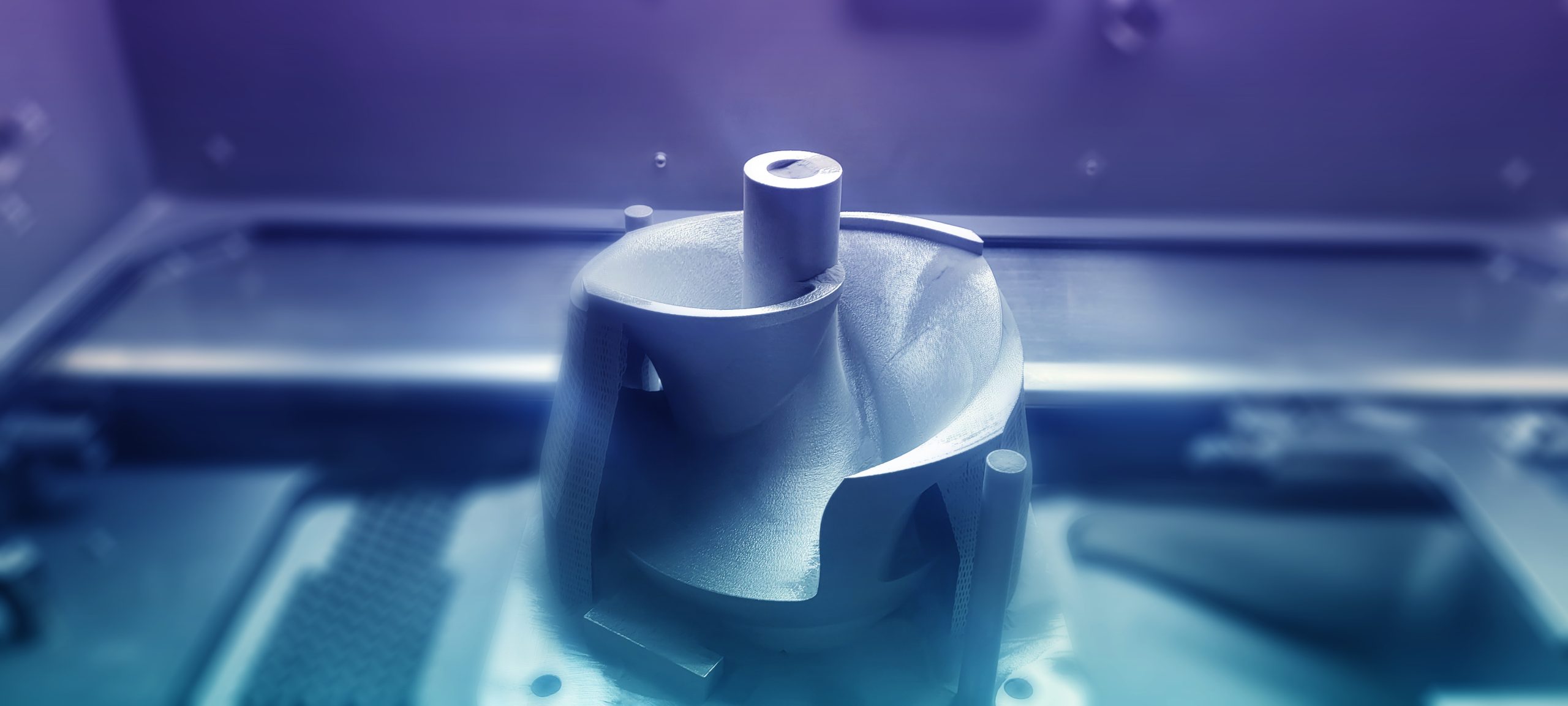

- Digitizing critical components via 3D scanning and reverse engineering.

- Storing validated design assets in secure digital spare parts libraries.

- Partnering with certified local manufacturers for on-demand spare parts production close to the point of use.

Results already show the impact:

- Lead time cut from 28 weeks to 5 days for a precision component.

- 1,000+ rarely used parts digitized, reducing physical holdings by 40%.

- A regional utility produced and installed a critical part within 72 hours, avoiding a six-week outage.

Why This Shift Matters Now

This shift is more than an efficiency upgrade; it’s a resilience and localization strategy. Spare parts digitization helps operators:

- Reduce downtime and extend asset lifespans.

- Minimize exposure to unpredictable supply chains.

- Optimize capital, lowering unnecessary inventory costs.

- Align with national strategies in the GCC and beyond that prioritize technology localization, supply chain independence, and advanced manufacturing.

Across the GCC (UAE, Saudi Arabia, Oman, Kuwait) and globally, companies are moving from firefighting to foresight by building digital spare parts ecosystems.

The energy and industrial sectors are at a turning point. Companies that adopt digital spare parts strategies today will lead in reliability, cost control, and operational readiness. Those who delay will continue to face mounting downtime costs and supply chains that no longer deliver.

In industries where every hour counts, the time to digitize your spare parts strategy is now.

Frequently Asked Questions

What is spare parts digitization?

Spare parts digitization is the process of scanning, reverse engineering, and storing parts in secure digital libraries. These digital assets can then be produced on demand using certified local manufacturing.

Why is spare parts digitization important for energy companies?

It reduces downtime, eliminates reliance on long global supply chains, lowers costs from overstocking, and ensures obsolete parts can still be sourced quickly.

How does spare parts digitization reduce lead times?

By creating validated digital designs that are ready for local on-demand production, companies can cut lead times from months to weeks.

Which regions are leading in spare parts digitization?

Energy companies in the GCC (UAE, Saudi Arabia, Oman, Kuwait) are pioneering proactive strategies that align with localization and advanced manufacturing priorities.

How can Immensa help?

As the Global Leader for Digital Spare Parts, Immensa helps operators digitize, qualify, and manufacture critical components locally to ensure operational resilience.