At Immensa Technology Labs, when designing molds for the construction industry, we use static simulation software to estimate the maximum stresses and displacements that will be produced in the 3D printed parts under operating conditions. This way, we are able to design and fabricate molds that can withstand the high loading forces characteristic of the industry. The steps involved in designing and simulating the forces acting on a wall structure are highlighted below.

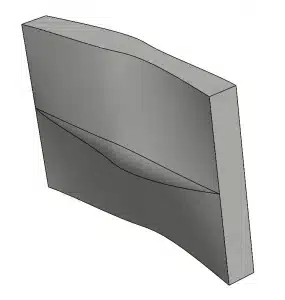

STEP 01 WALL DESIGN

A 3D model of the structure to be constructed is designed

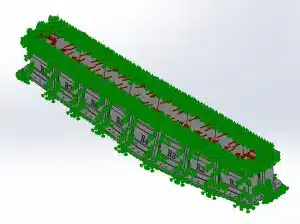

STEP 02 MOLD DESIGN

A 3D model of the structure to be constructed is designed

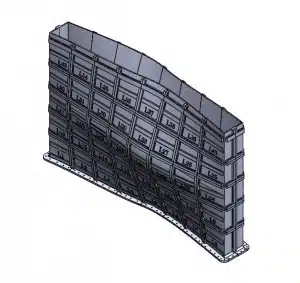

STEP 03 MODEL SIMPLIFICATION

The mold design is simplified, whilst maintaining all key elements, in order to reduce computational costs

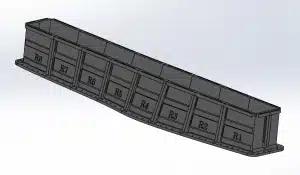

STEP 04 LOADS & BOUNDARY CONDITIONS

The operating pressures, fixture points, 3D printing material, and other parameters are fed into the simulation software

STEP 05 RESULTS

The stresses and strains on the mold are analyzed and modifications made if necessary