“The most frightening aspect of this crisis is not the short-term economic damage it is causing, but the potential long-lasting disruption to supply chains”

Shehzad H. Qazi, the managing director of China Beige Book, wrote in Barron’s on Friday.

3D Printing was quickly becoming a mainstream technology, then global supply chain got hit by Coronavirus. A rapidly growing technology just received a major boost from an unexpected crisis.

Technology Adoption in Times of Crisis

Throughout history, diseases, pandemics, and wars have always been triggers in the widespread adoption of technology. They expediate the conversion of the masses from traditional methods to proactively embracing technology, making it the new norms.

As we have all seen over the past few weeks, the shares of teleconferencing platforms such as Zoom have skyrocketed with more companies enforcing remote workplaces and cancelling face-to-face meetings. Homeschooling is rapidly picking up too, as more schools are closing for precautionary measures. Coronavirus is the perfect definition of a black swan event.

The Coronavirus is causing havoc across the global supply chains, which will only escalate further over the coming months. Businesses across the world had planned for the closure of Chinese manufacturers during the Chinese New Year’s which ended February 8th. However, no one was prepared to have their supply chain being disturbed beyond mid-February. Companies that rely on Chinese imports such as auto companies to electronics retailer and many others will start running short on supplies before the end of March. With the exception of a limited number of US based manufacturers, the majority of the world’s companies are not ready to disconnect from China and have no contingency plans. US companies have been dealing with the US-China trade war for the past few years and were actively addressing supply-chain risk management. However, many companies follow a more reactive approach in responding to supply-chain disruptions. As stated by Forbes magazine, “Under President Trump, that slow-moving panda moved a little faster. Companies didn’t like the uncertainty of tariffs. They sourced elsewhere.” Coronavirus is pushing the moving panda significantly faster.

How does that affect Additive Manufacturing (and Industrial 3D Printing)?

Is this the trigger that pushes the adoption of Additive Manufacturing into high speed?

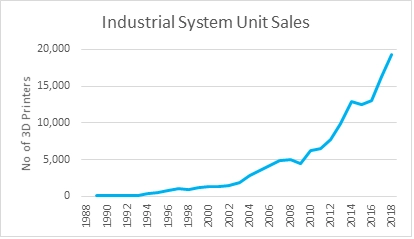

Since 2018 we have seen the adoption of Additive Manufacturing rising at an average rate of 36% year-on-year. 3D Printing is witnessing the fastest growth rate of any technology in the history of manufacturing. Yet its total direct market was less than US$20 billion in 2019. That is rapidly changing. A McKinsey report states that they believe the overall economic impact created by Additive Manufacturing will range between US$100 billion to US$250 billion by 2025.

Source: Wohler’s Report 2019

Source: Wohler’s Report 2019

As powerful trends have disrupted different sectors around the world, we are now witnessing the impact of technology affecting the manufacturing industry. Additive Manufacturing provides the most effective and fastest method of meeting companies’ needs when it comes to spare parts and components required for their operations. The process of moving from the physical storage of parts to the digital storage of parts and producing the part on demand when required is being adopted by most major corporations. Virtual Warehouses will become the norm (click here to read more about how Digital Inventory works).

As progressive organizations are rapidly and systematically reviewing supply chain set-up, we are seeing more emphasis on localization of supplier footprint. To enable localized manufacturing, there is a need for agile production facilities. Traditional manufacturing requiring significant Capex and volume-based production doesn’t work anymore. Manufacturing must be able to produce a range of parts using the same equipment. This is what 3D Printing technology is all about. 3D Printing drastically decreases the tooling-up load needed to start production.

Distributed Manufacturing and 3D Printing

World Economic Forum identified Distributed Manufacturing* as one of the 10 emerging technologies in 2015. Additive Manufacturing noted as the key enabler for the implementation of Distributed Manufacturing. Fast forward 5 years and Additive Manufacturing has caught on. Over 70% of the world’s manufacturers are using 3D Printing in some form. However, only 0.8% of total manufacturing is done using 3D Printing. As this percentage grows, we expect a massive transformation in the global economy and how it functions. It was estimated that within 10 years at least 5% of the world’s manufacturing will be done using 3D Printing, that equates to manufacturing value in excess of US$650 billion. Coronavirus will likely play a chief role in shortening that timeframe.

That means distributed-manufacturing supply chains aren’t just viable; they will be a pivotal part of the new manufacturing and design eco-system. Currently, companies are making hundreds of thousands of one item. They do a piece in one step, and then it goes to another machine for the next step. This process is being disrupted by Additive Manufacturing and reconciling the processes, whereby one machine can produce various items at once. A rapid sprout of micro-manufacturing facilities will chip away at the old ways of centralized mass manufacturing.

Distributed manufacturing has the ability to transform industries on the same scale as that of the industrial revolution.

I will leave you with a quote from Lou Rassey, CEO of Fast Radius a US based company that was acquired by UPS. “One of the leading applications of 3D printing and logistics is for virtual warehouse applications, where companies are storing parts digitally in a cloud and producing them on demand when they need them for applications, as opposed to storing them physically in a box on a shelf in a warehouse,”

*Note: Distributed manufacturing turns on its head the way we make and distribute products. In traditional manufacturing, raw materials are brought together, assembled and fabricated in large centralized factories into identical finished products that are then distributed to the customer. In distributed manufacturing, the raw materials and methods of fabrication are decentralized, and the final product is manufactured very close to the final customer.