Digital Warehousing

Immensa360 is a proprietary digital warehousing solution that offers a digital spare parts library with end-to-end supply chain optimization for clients in the energy sector.

It provides an all-around service that covers the full transformation journey of physical spare parts from digitization to digital asset creation and accessibility in Immensa’s digital inventory platform, ready to be produced locally and on-demand via additive manufacturing.

Benefits

Lowers inventory costs

Ensures critical and obsolete parts availability

Streamlines ordering process

Key Features

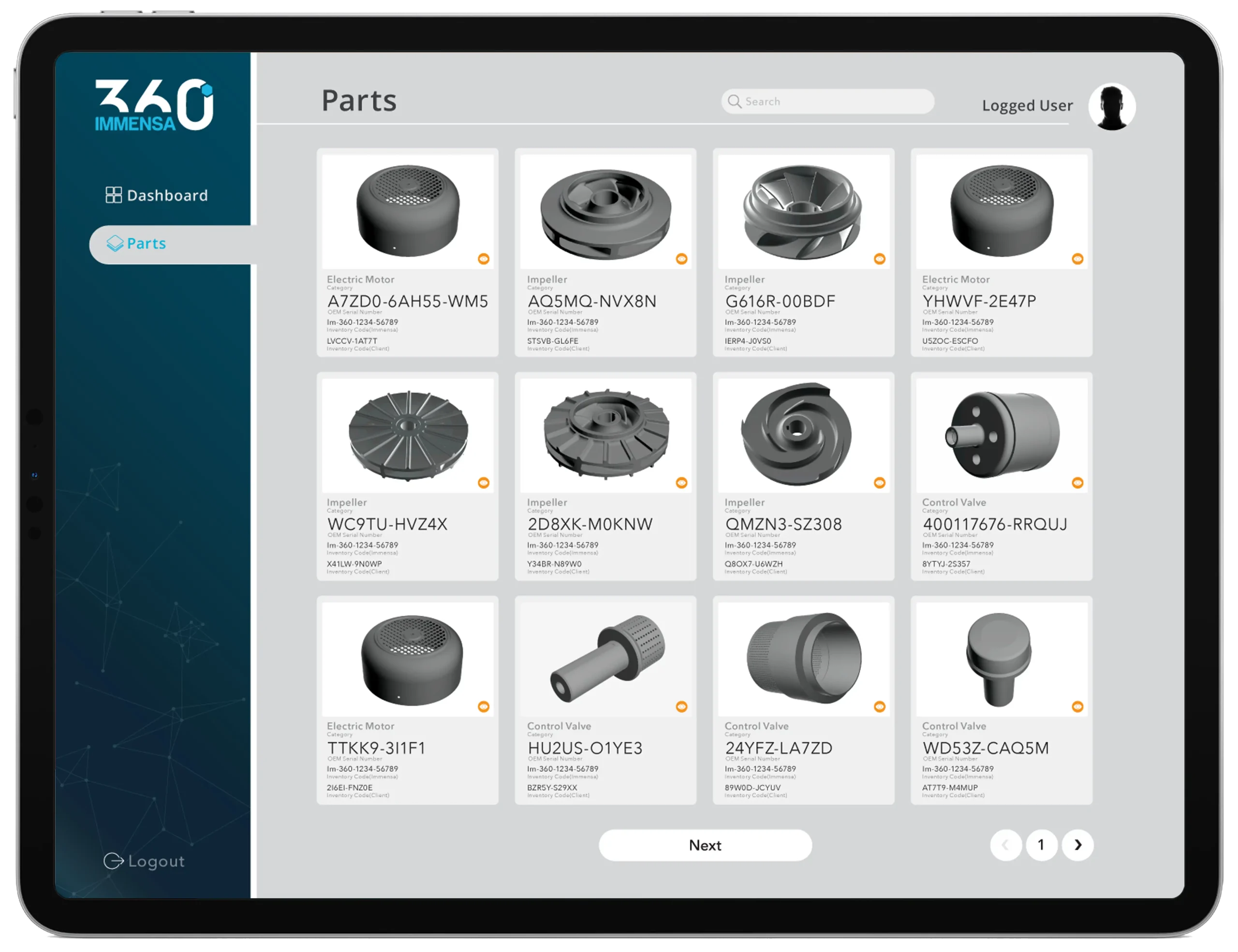

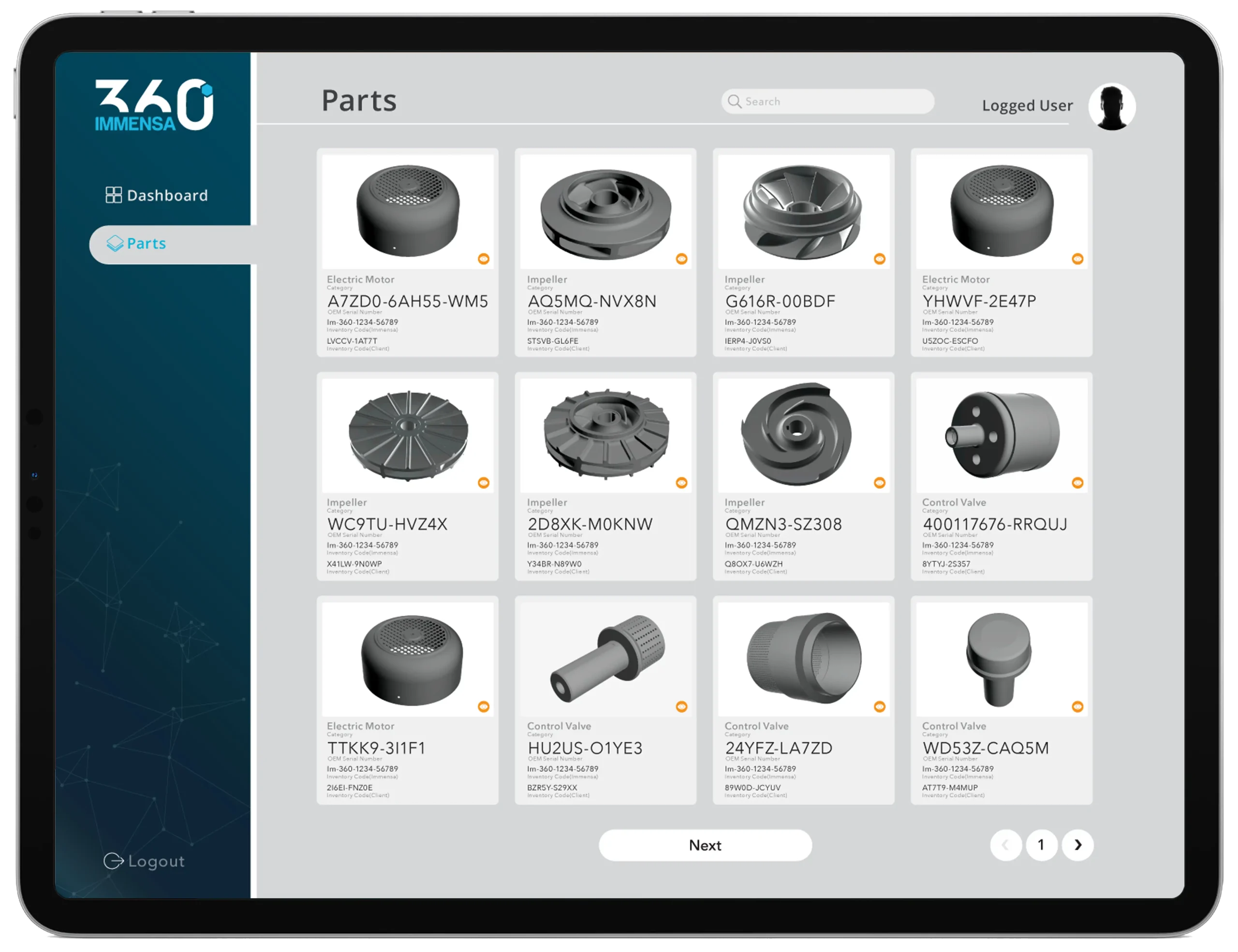

Digital Library

Get a dedicated portal that offers convenient access to our easy-to-use and comprehensive spare parts data library.

Digital Asset Drawings

Access your digitized spare parts with over 50 data points in either 2D or 3D via the Digital Passport.

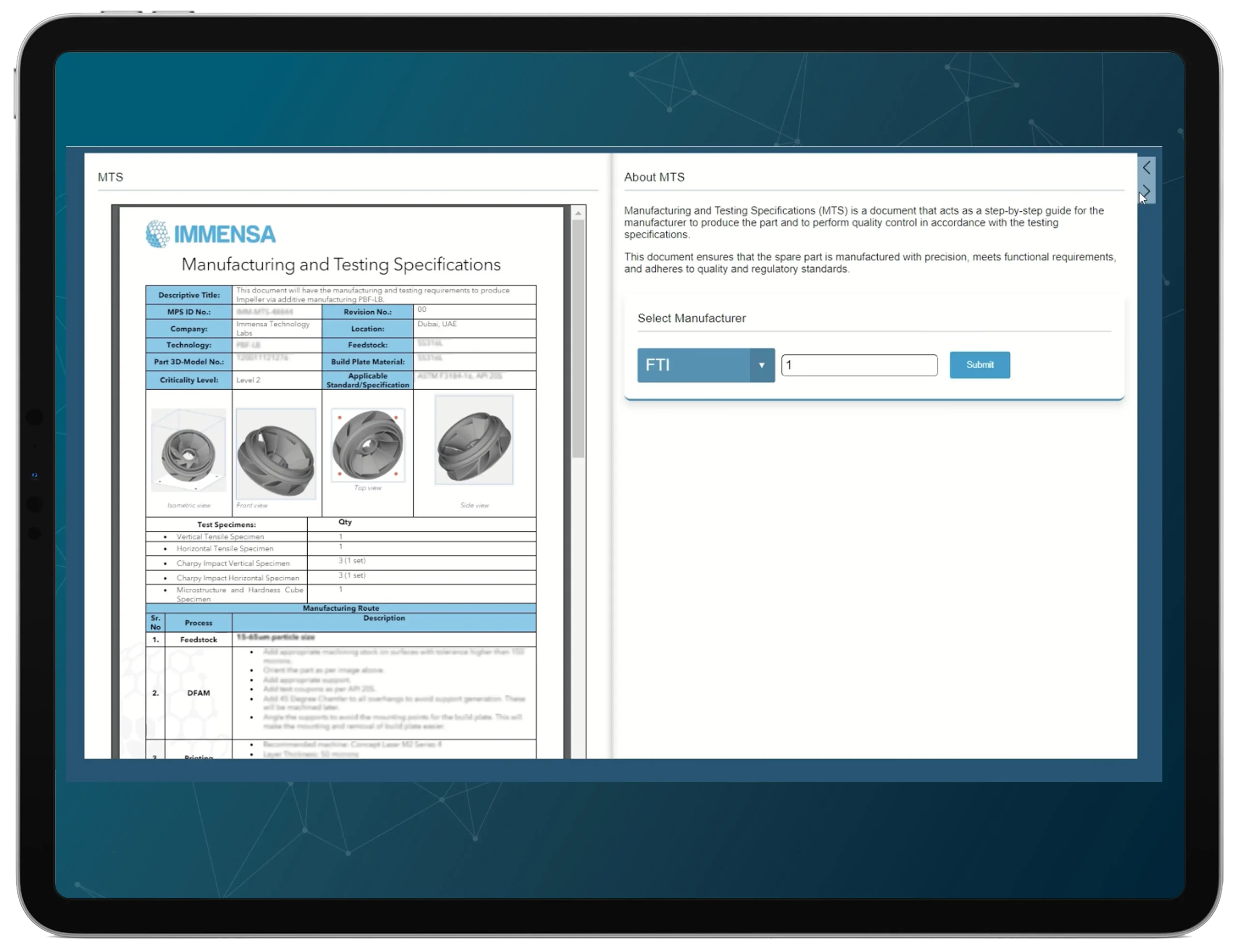

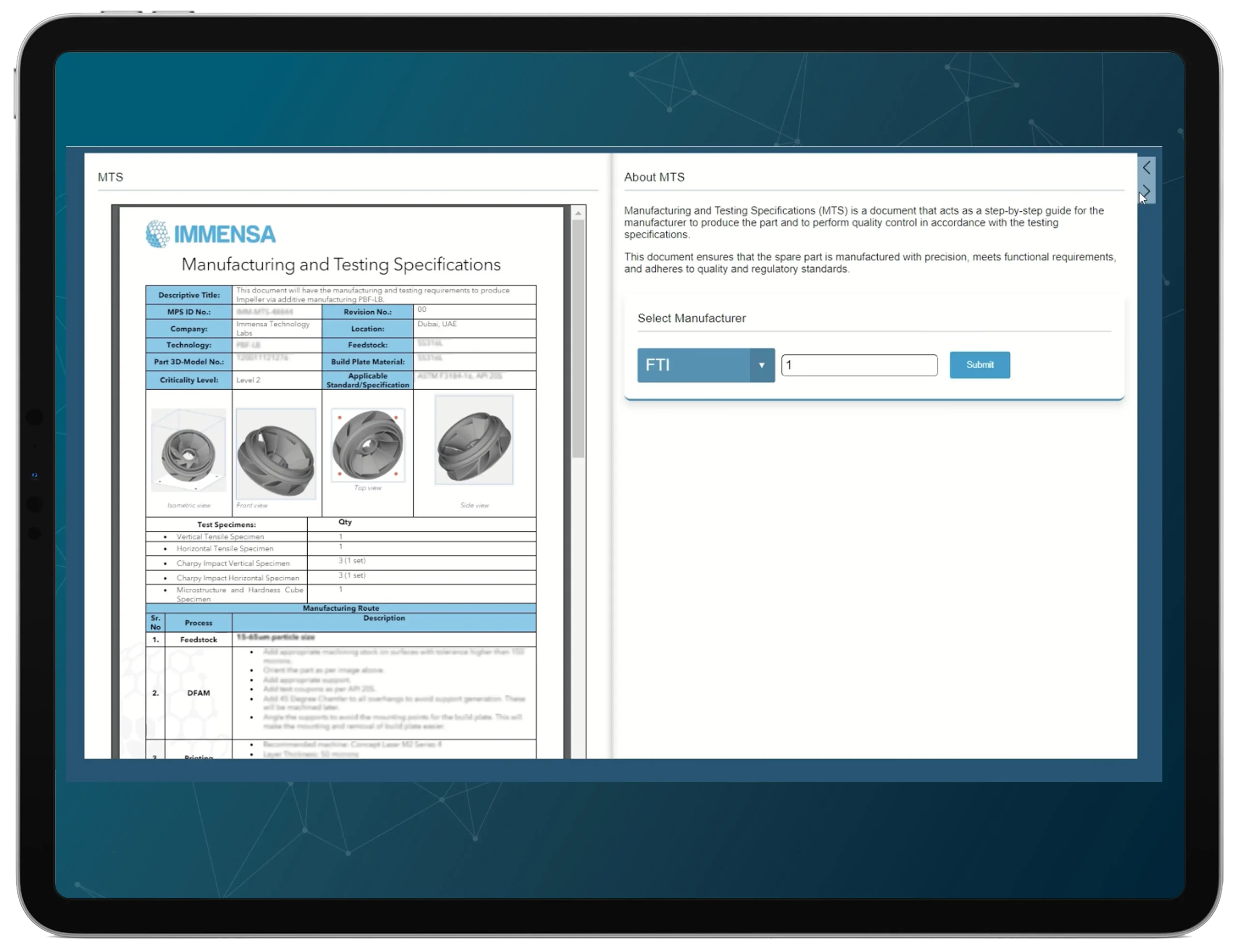

Manufacturing and Testing Specifications (MTS)

Browse the comprehensive guide for manufacturers that details how to produce each spare part through additive manufacturing and conduct quality control tests.

Includes orientation details, manufacturing pathways, and quality control testing requirements.

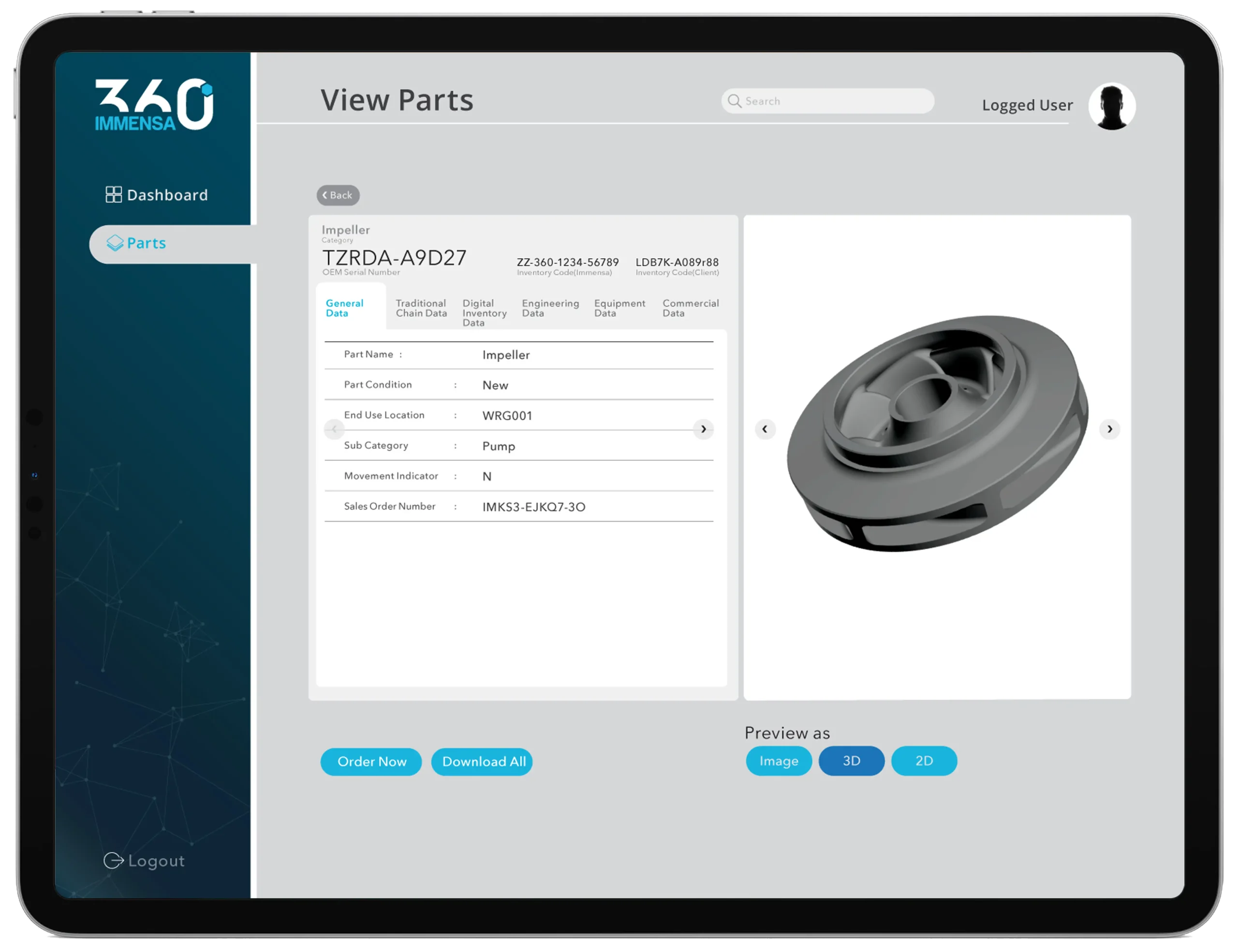

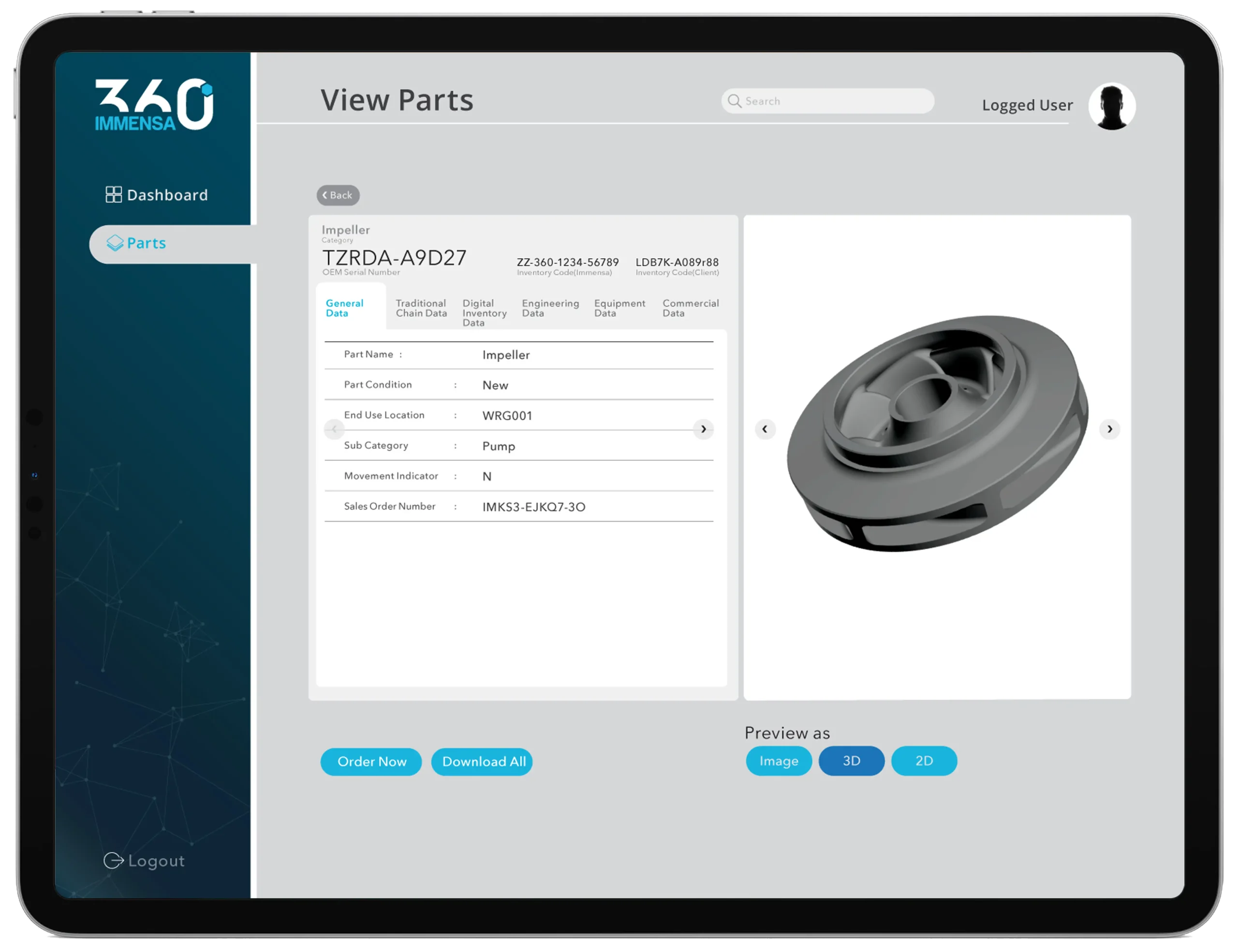

Digital Passport

Interact with individual spare part files through a flipbook-style digital passport that contains all relevant manufacturing details, including more than 50 data points per part, and an easy “Click-to-Order” feature for on-demand manufacturing requests.

Includes:

- Details Overview

- 2D & 3D Viewer

- MTS Viewer

Key Features

Digital Library

Get a dedicated portal that offers convenient access to our easy-to-use and comprehensive spare parts data library.

Digital Asset Drawings

Access your digitized spare parts with over 50 data points in either 2D or 3D via the Digital Passport.

Manufacturing and Testing Specifications (MTS)

Browse the comprehensive guide for manufacturers that details how to produce each spare part through additive manufacturing and conduct quality control tests.

Includes orientation details, manufacturing pathways, and quality control testing requirements.

Digital Passport

Interact with individual spare part files through a flipbook-style digital passport that contains all relevant manufacturing details, including more than 50 data points per part, and an easy “Click-to-Order” feature for on-demand manufacturing requests.

Includes:

- Details Overview

- 2D & 3D Viewer

- MTS Viewer

Secure Your Spare Parts Supply Chain

Immensa stores your digital spare parts in a secure data repository with advanced security operations and automated backup processes.

Our 24/7 proactive monitoring services and best-in-class encryption protect the data for each digital asset to ensure any potential security threats are identified and addressed promptly.

Frequently

Asked Questions

What is digital warehousing?

Digital warehousing is an innovative approach to spare part supply chains that significantly reduces overhead costs and eliminates the risk of part obsolescence by creating an online inventory for “digital twins” of physical spare parts, which are securely stored, and are available for on-demand production.

How can I get digital versions of my physical spare parts?

Physical spare parts may be digitized by submitting them for 3D scanning and data capturing to be transformed into digital spare parts.

You may visit our Digitization page to learn more about how to convert your spare parts from physical to digital.

Which data points are available for each part?

Immensa360 provides access to more than 50 Data Points for each digitized spare part. These data points are categorized under General Information, Traditional Supply Chain, Engineering, Equipment Data, Digital Inventory, and Quality Assurance.

Resources

Additive Manufacturing of Titanium Impellers

Applying additive manufacturing (AM) to oil and gas spare parts supply chains unlocks multiple advantages, including operational, financial, and environmental benefits. AM technologies can enhance existing supply chains and eliminate the need to stock up on physical...

Towards a Sustainable Industry

This whitepaper highlights the significant role of Digital Warehousing and Additive Manufacturing in advancing the sustainability of industrial supply chains, with a special focus on the energy sector. It details how these technologies collectively reduce carbon...

Latest Reads

5 Ways Immensa Ensures IP and Data Security in Digital Manufacturing

The Future of Manufacturing: From Physical to Digital

Digital Warehousing: The Future of Spare Part Supply Chain

Digital Warehouse Solutions for Parts Acquisition