Is it time for your company to invest in Additive Manufacturing? Something every CEO should think about when it comes to 3D Printing.

For the past few years, we have been hearing a lot about Additive Manufacturing or 3D Printing as it is more commonly referred to. It all started in 2016 when His Highness Sheikh Mohammed bin Rashid Al Maktoum announced the Dubai 3D Printing Strategy, followed by Saudi Aramco Energy Ventures investing in 3D printing manufacturer Desktop Metal, then Strata 3D printed an aircraft cabin part for Etihad, and then Immensa working with DHA to 3D print prosthetic legs for an Emirati double Amputee, or Consolidated Contractors Company transforming its business and adopting 3D Printing to produce all their spare parts, to other news whereby houses and offices were being 3D printed across the UAE. It felt like 3D printing was rapidly changing the world we live in. It seemed we were getting close to each having a 3D printer in our houses and 3D print everything we need? Construction will be disrupted; retail will become extinct, and any company in manufacturing will cease to exist.

THE FUTURE OF 3D PRINTING IN DUBAI

Is this a reality, obviously not. A good analogy is to think of the sewing machine. When sewing machines where first commercialized people started prophesying that it’s the end of retail as we know it, the business models of Marks and Spenser and other cloth retailers will vanish as every home will have a sewing machine and make their own clothes. Same can be applied to 3D printers.

3D Printing will have its place in homes, but it will be for specific uses and the fact that the technology has been around for over two decades provides us with a lot of information and insight on where it is heading and its capabilities.

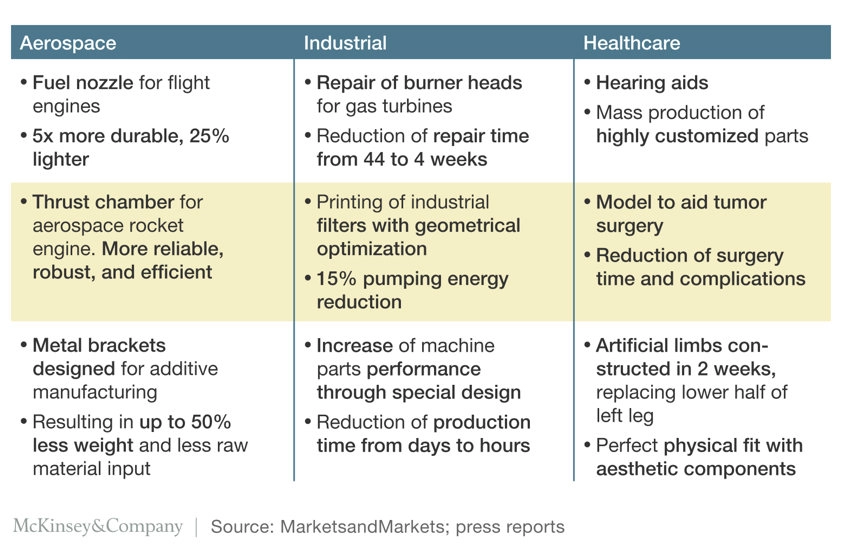

3D Printing for certain will revolutionize the manufacturing process, and it will definitely change how many things are being produced, but it will happen gradually. We believe 3D Printing technology will not displace the various traditional manufacturing processes but will get integrated and operate alongside conventional manufacturing. The technology will have a role to play in every industry. Organizations that have not already started exploring how to leverage this rapidly growing technology will find themselves falling behind and ultimately less competitive.

3D PRINTING IMPACT ON THE INDUSTRIES

The range of impact in each industry will differ, where certain sectors such as logistics and supply chain will likely see significant disruptive changes as a result of 3D Printing, while other such as Marine the effect will be indirect. Deloitte has a paper on Supply Chain disruption published back in 2015 where most of what they discussed has become a reality, and there is much more information on this topic.

AM technology represents a potentially valuable area for investigation and investment as companies consider ways to improve supply chain performance. Indeed, Deloitte’s research has found that higher-performing supply chain leaders are already using AM in this way.

Source: September 02, 2015 Deloitte Article – 3D opportunity for the supply chain: Additive manufacturing delivers

Where do you start as a company? Education and awareness. Invest in educating your workforce and teams on what is additive manufacturing, whether you retail cosmetic products or manage shipyards, it’s imperative that your workforce understands what Additive Manufacturing is and what it does.

Why 3D print a mascara? It’s all in the brush delivery. The high-tech mascara wand boasts technology that works to make the most out of the mascara formulation through clever application ability. The micro-cavities printed in the brush allow the mascara formula to absorb, delivering exactly the right amount to lashes allowing it to be built up to increase lash volume without having to re-dip the brush back into the mascara tube between each application. And because of the “granular texture” of the brush, it helps the mascara stay put, adhering to each lash more easily. Each bristle has been printed and arranged in millimetre-scale so that it creates volume, definition and ensures zero clumping. Let’s hope they’ve printed enough to go round.

3D Printing is a reality and its been around for over two decades. It has gradually found its place in certain sectors and its use and adoption is rapidly growing. The same way organizations started preparing themselves to online business and web presence, it is time for organizations across all industries to start undertaking how and where 3D Printing will play a role. Is it in prototyping, or in customized manufacturing, or spare parts, or tooling, or is it in mold making. The applications are limitless, the question that you need to ask yourself where can it ADD VALUE in my organization.

Whether you are a CEO of a multi-sector organization or a division manager in a mid-size company, you need to start building awareness within your teams. You need to look at how you can leverage this technology to benefit your business. What role can it play in your operations?

I will end this blog with an example of one company that has been a big adopter of 3D Printing. Caterpillar started experimenting with 3D Printing back in 1991. It’s been said that they set an internal challenge to their teams to try and find 15 applications suited for 3D Printing in 30 days. The various teams came back with 32 viable applications within the 30 days. To read more, go to Caterpillar’s website.

Today Caterpillar has come a long way, from buying one 3D printer in 1991 to placing 3D printers at each of their locations and offices and in 2016 establishing their own Additive Manufacturing Factory with numerous industrial 3D Printers.

It was said best by Stacy DelVecchio, Additive Manufacturing product manager at Caterpillar Inc., when she said that the best strategy when it comes to 3D Printing might be to “think big, start small, and act fast.”

Other useful and interesting information and news on Caterpillar and 3D Printing.

Download Ernst & Young paper titled “Why 3D printing needs to be on the business executive agenda now“