Digitization

Take the first step towards digital warehousing and on-demand additive manufacturing for your spare parts supply chain with Immensa’s Digitization services.

Minimizes storage costs

Protects from parts obsolescence

Optimizes part design & performance

How It Works

AI-powered Inventory Assessment

Technical Assessment

Checks whether parts are viable for additive manufacturing based on the materials, criticality, and part applications involved.

Commercial Assessment

Identifies the commercial viability of printing or digitizing a spare part based on lead time, production costs, and demand.

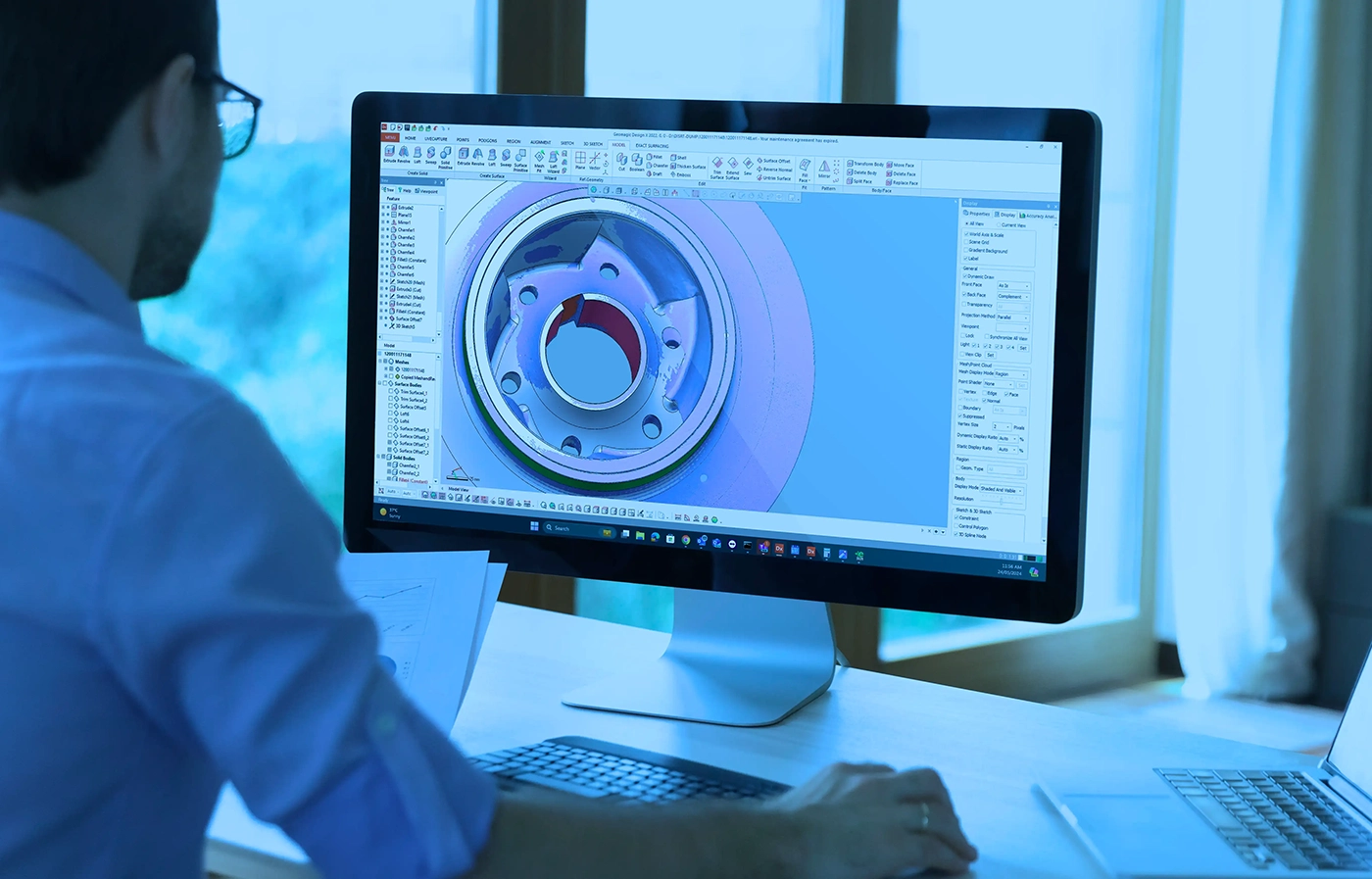

3D Scanning and Data Capturing

Enables reverse engineering by accurately capturing the geometric data of physical spare parts to create “digital twins”.

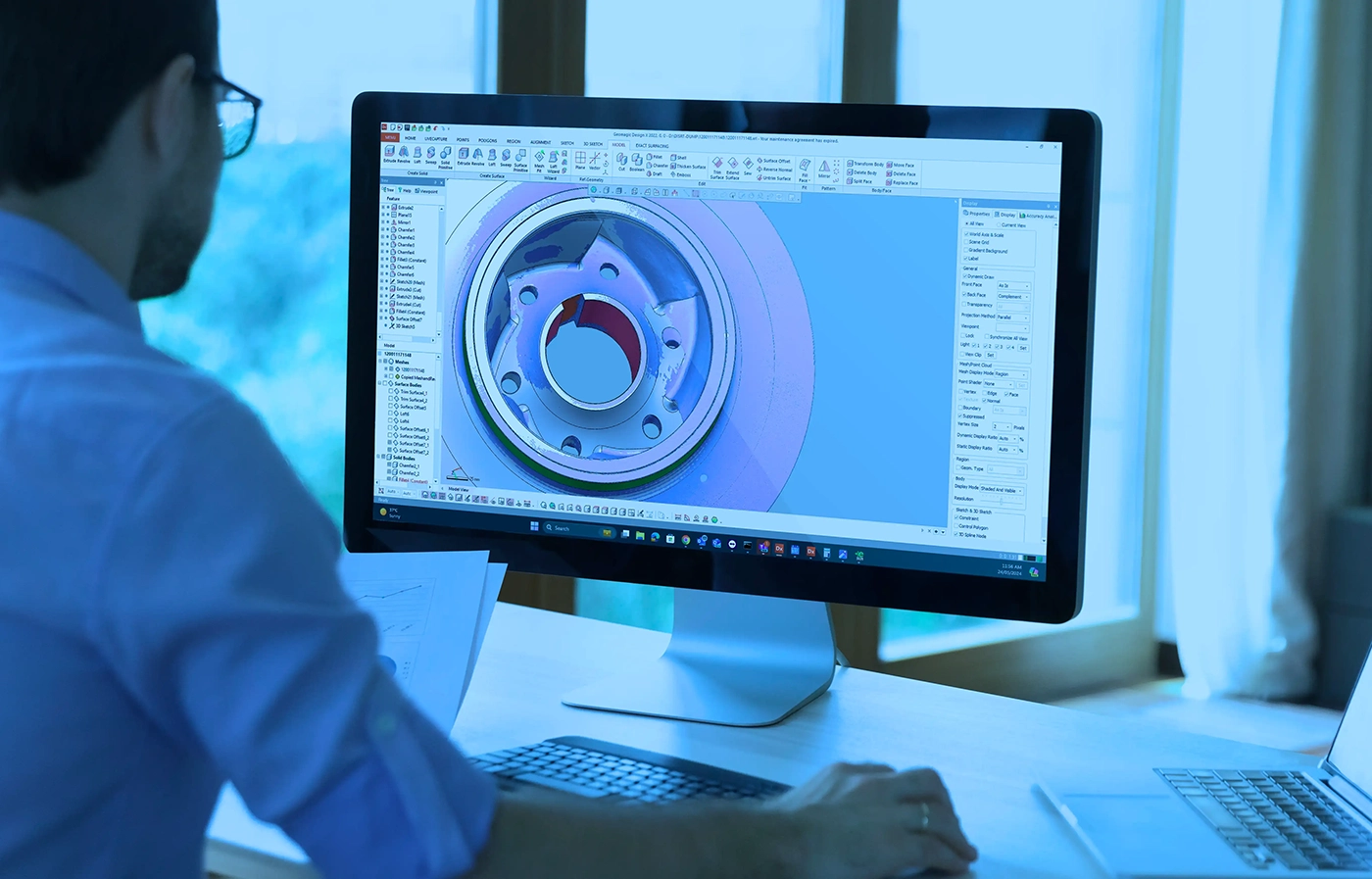

Data Processing

Analyzes, optimizes, and extrapolates spare part designs, ideal for legacy components with missing or incomplete original design data.

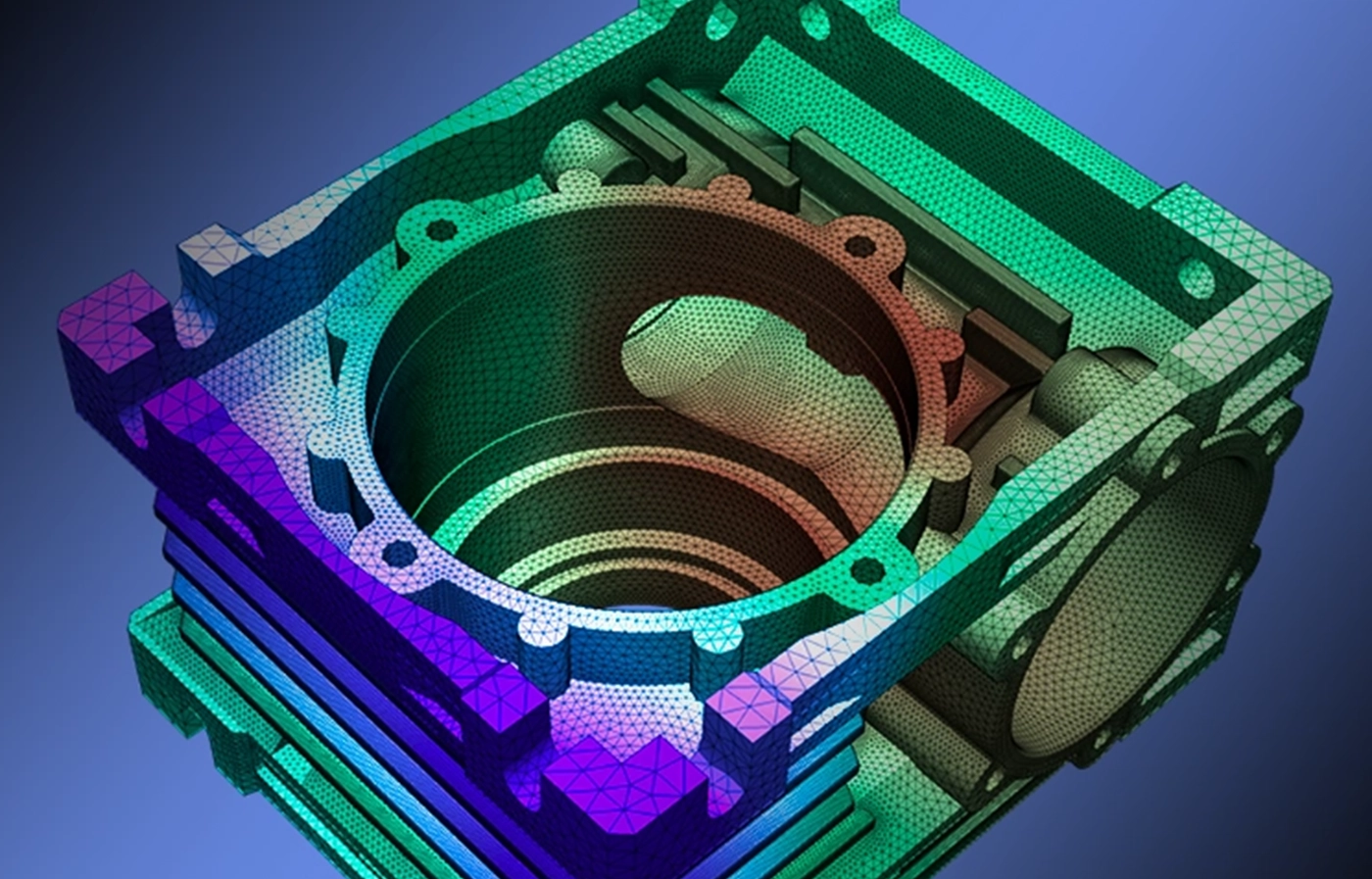

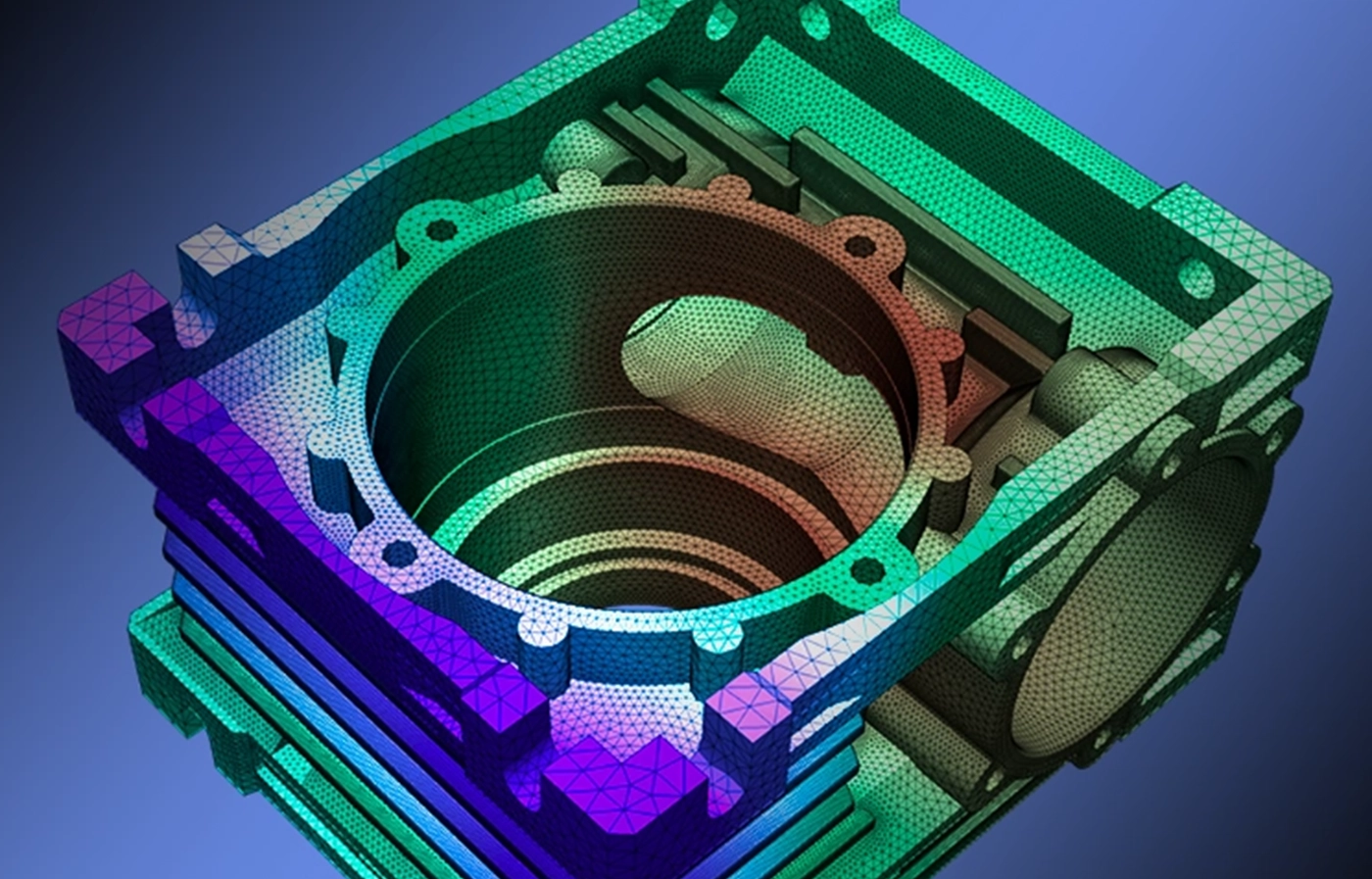

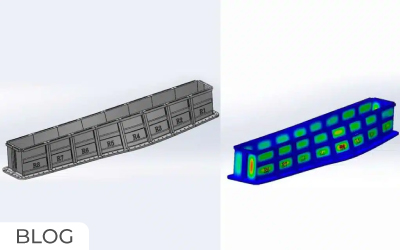

Testing & Simulation

Runs the digitized spare part through thermal, structural, and flow simulations.

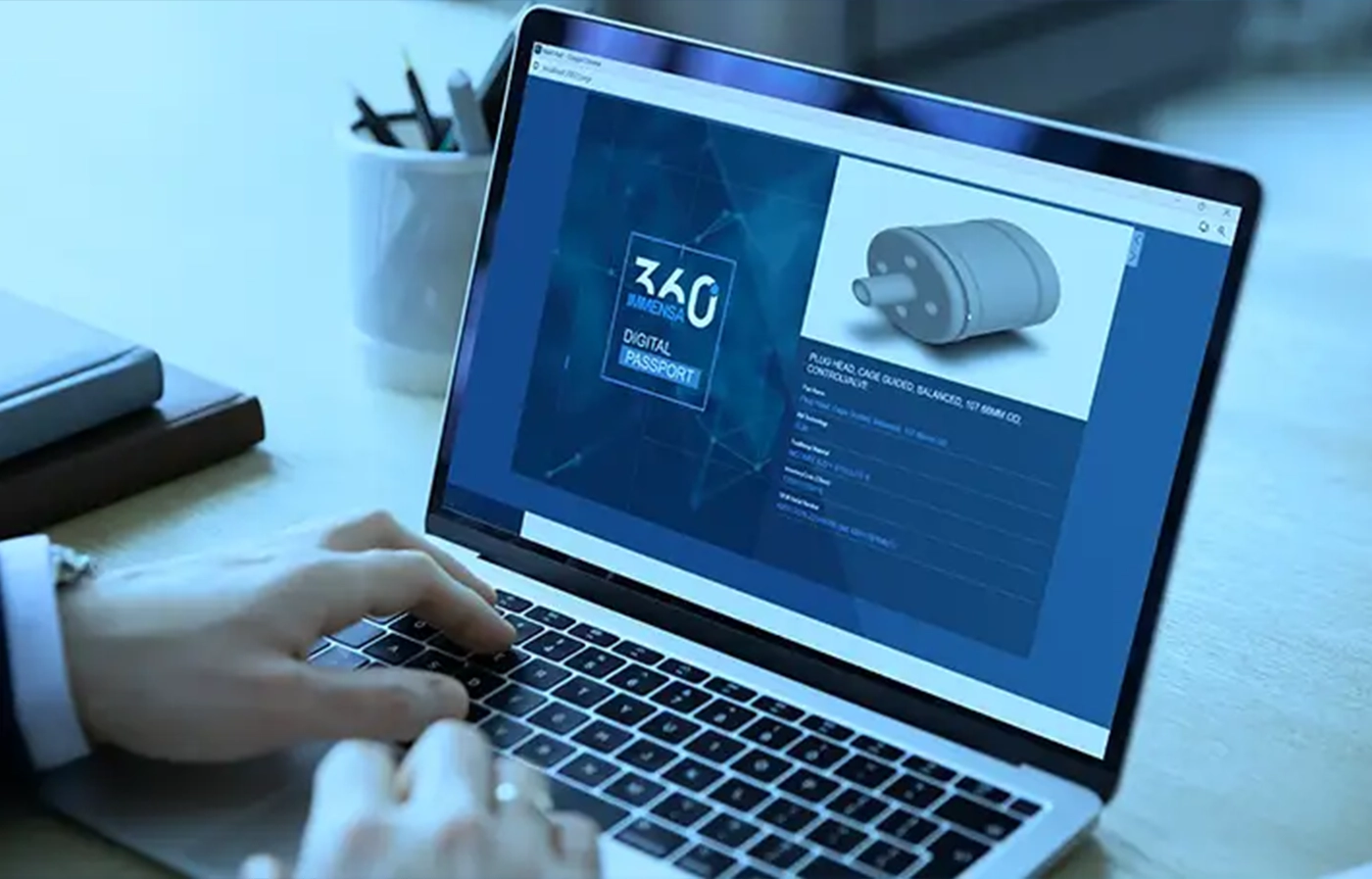

Digital Asset Creation

Compiles all relevant manufacturing details in an easy-to-use digital passport to enable on-demand production for every digitized spare part.

How It Works

AI-powered Inventory Assessment

Technical Assessment

Checks whether parts are viable for additive manufacturing based on the materials, criticality, and part applications involved.

Commercial Assessment

Identifies the commercial viability of printing or digitizing a spare part based on lead time, production costs, and demand.

3D Scanning and Data Capturing

Enables reverse engineering by accurately capturing the geometric data of physical spare parts.

Data Processing

Analyzes, optimizes, and extrapolates spare part designs, ideal for legacy components with missing or incomplete original design data.

Testing & Simulation

Runs the digitized spare part through thermal, structural, and flow simulations.

Digital Asset Creation

Compiles all relevant manufacturing details in an easy-to-use digital passport to enable on-demand production for every digitized spare part.

Frequently

Asked Questions

How can I get my digital spare parts manufactured?

With Immensa, you can have your spare parts produced on-demand through our in-house additive manufacturing services or through our global network of manufacturers.

How do you scan the internal features of the parts?

Immensa’s data capturing team creates a mold of the part’s internal structure and then scans it to ensure that internal features are digitized accurately.

Can the digitization be done in our own facilities?

Yes. Our team is fully equipped to conduct data capturing on client premises, while the rest of the digitization process will be carried out at the Immensa facility.

Resources

Additive Manufacturing of Titanium Impellers

Applying additive manufacturing (AM) to oil and gas spare parts supply chains unlocks multiple advantages, including operational, financial, and environmental benefits. AM technologies can enhance existing supply chains and eliminate the need to stock up on physical...

Towards a Sustainable Industry

This whitepaper highlights the significant role of Digital Warehousing and Additive Manufacturing in advancing the sustainability of industrial supply chains, with a special focus on the energy sector. It details how these technologies collectively reduce carbon...

Latest Reads

Why Energy Companies Must Shift from Reactive to Proactive Spare Parts Strategies

Modernizing the Spare Parts Market Through Digitalization and Sustainability

3D Printing Cost Reduction Using Weight Optimization

Simulating Structural Forces on 3D Printed Molds